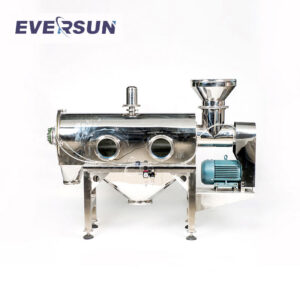

Industrial Sieving Machine

- Diameter of screen(mm): 520-1390

- Sieving precision: ≤500 mesh or ≥0.028mm

- Layer: 1

- Power(KW): 0.12-0.55

- Product type: Automatic

- Structure material option:316L stainless steel, 304 stainless steel, carbon steel.

- Customize service:All parts can be customized

- Application:grain, pharmacy, beverage, chemcial, etc.

- Price(USD): 1500-8000

- Application: Powder, Granules, Liquid, Bulk Solids and other ingredients.

- Description

- Inquiry

Product Introduction

Industrial Sieving Machine, widely known as “safety officer”, can be used in the feeding system at the front end of the production line of coffee powder, spices, small foods, solid beverages, etc. It can do the check screen or safety screen and efficiently separate foreign materials and over-size particles in raw materials (flour, coffee powder, milk powder, additives, etc.).

It is connected to the production system and does automatic separation much more rapidly than other kinds of sieving machines.

The industrial sieving machine uses a or two high-frequency vibration motors as the excitation source. After the material enters the sieving machine, it is subjected to three-dimensional rotary motion on the screen surface by the vibration source force. The powder and the agglomerate are fully dispersed and separated rapidly, while qualified materials go into the lower chamber with foreign matters and over-size particles being discharged to the slag discharge port.

Features & Advantages

Features & Advantages

1. Improve the purity of materials

Foreign matters and oversized materials will be removed from the materials

2. Extremely high capacity

The check screener can do the separation much more rapidly than other traditional screeners.

3. Taking smaller areas

Compared to traditional screeners, the check screener is very small and easy to fit into limited space.

4. Dust free

The fully enclosed structure makes no dust leak during the working process.

5. Reduce production downtime

The machine can be easily cleaned without tools and the mesh can be replaced within several minutes

6. Low noise

Ultra-quiet bass design, the working sound is only 70dBA

7. Low maintenance cost and long service time

With excellent motors and parts, the screener can work for a very long time without any problem.

Application Industries: Powder, Granules, Bulk Solids, Liquid and other ingredients

(Materials below are just parts of our material list, for a complete list, please consult us)

- Chemical industry: resin pigment, medicine, grease, paint, palette, cosmetic, etc.

- Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc.

- Metallurgy industry: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electric magnetic material, polishing powder, refractory material, etc.

- Mining industry: kaolin, alumina, carbon, quartz sand, titanium oxide, zinc oxide, etc.

- Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

- Mechanical industry: casting sand, powder metallurgy, electromagnetic material, and metal powder, etc.

- Paper-making industry: coated slurry, exhaust liquid, paper-making liquid, and wastewater reclamation, etc.

- Pollution treatment: waste oil, wastewater, additives, activated carbon, etc.