Product Introduction

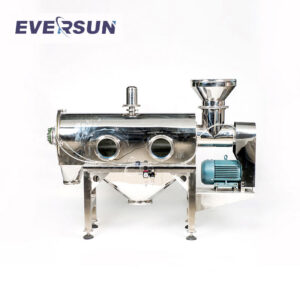

The use of ultrasonic vibrating sieve is mainly to solve the light weight, easy reunion, There is static wait for difficult screening material setbacks. Ultrasonic vibrating sieve with high precision, large processing quantity, simple structure, low energy consumption, low noise, long service life of the screen, good sealing performance, no dust overflow,convenient repair, Can be used for the automation of assembly line production work. Ultrasonic vibrating sieve is widely used for chemical industry, Dry powder materials, plastics, pharmaceutical, food, building,materials, metallurgy, glass, food,chemical fertilizer, abrasives, dry powder material in the ceramic industry the sieving. Compared with rotary vibrating screen, ultrasonic vibrating sieve is equipped with a ultrasonic generator, with self-cleaning function ,the mesh is not easy to block, it is no need to add bouncing balls and other anti blockage device.

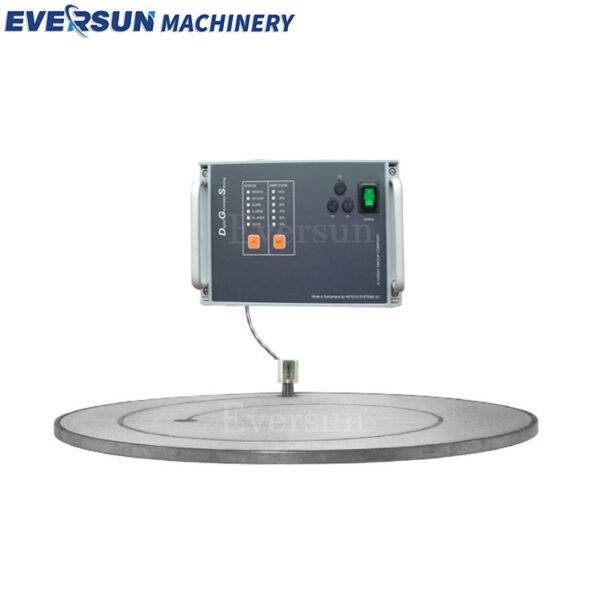

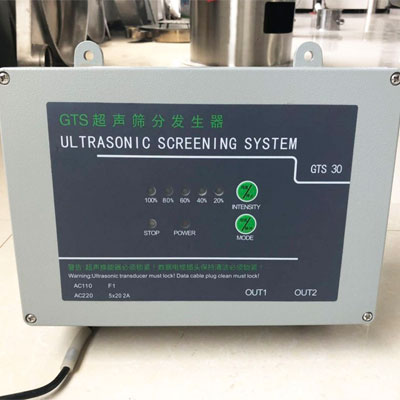

Ultrasonic vibrating sieve uses intelligent vibrating ultrasonic vibrator to realize the organic combination of ultrasonic and vibrating screen, which can solve the sieving problems of fine powder due to strong adsorption, easy agglomeration, high static electricity, high precision, high density, light specific gravity, etc. The screen passing rate of the ultrasonic vibrating screen is increased by 5-20 times, and the material is not blocked. The composition of ultrasonic vibrating sieve: roof, small beam ring, ultrasonic grid, ultrasonic transducer, sieve, frame, the big beam ring, bottom grid, vibration plate, drive motor, damping spring, bottom tube, ultrasonic control box and other major parts. Mainly screening dry powder materials of 200 – 600 mesh. The ultrasonic grid is a high-frequency ultrasonic pulse cleaning sieve, which replace the simple automatic cleaning device of rotary vibration sieve. The screening efficiency is high and not blocking sieve mesh, it is the better separation equipment for fine powder screening industry.

EVERSUN ultrasonic vibrating sieve machine is composed of ultrasonic vibration system and vibro sieving machine. With unique technology, the EVERSUN ultrasonic system will transmit high-frequency micro vibration to the mesh. Plus the original vibro of machine, the sieving output, quality and capacity can be dramatically increased. Also mesh can do perfect self-cleaning to reduce the downtime for our clients.

The EVERSUN ultrasonic vibrating sieve machine changes the damage caused by the conventional screening method to the powder, especially ultra-fine powders and highly viscous materials, and the sieving throughput are increased efficiently. Also the abrasion of sieves will be reduced sharply so that the maintenance cost and downtime will get lower. Ultrasonic vibrating sieve offers better results of sieving for all kinds of powders especially sticky and difficult powders adding product quality and integrity.

With advanced engineering design, the EVERSUN ultrasonic system can be combined with various sieving machines, no matter they are new or already installed. EVERSUN group will provide suitable designs and solutions to meet the needs of clients. The EVERSUN ultrasonic vibrating sieve is effective to prevent screen clogging, solving the screening problem of materials with strong adsorption, easy to reunite, static electricity and light specific gravity such as metal powder. Ultrasonic vibrating sieve is the primary choice for processing fine powder,and combined with the ultrasonic system,it can effective to prevent screen mesh clogging and improve the product capacity.

Ultrasonic vibrating sieve Features and Advantages

- Dramatic increase of capacity——the processing volume is 2-10 times than that of ordinary screening machines

- Ultra fine grading available——the sieving size can reach up to 600mesh(0.023mm)

- Efficient for hard-to-screen materials——the materials like silicon carbide micro-powder, hard alloy micro-powder, coffee powder,etc can be screened efficiently

- Reduce frequency of cleaning sieve——low blocking and high throughput rate of sieve

- Low maintenance cost——reduce the damage rate of sieve and no need to repair and replace the mesh always

- Wide application——almost all kinds of sieving machines can use this system

Our Unique Service

For all our ultrasonic vibrating sieve machine, our factory will provide:

1. Detailed pre-sale sieving suggestion.

2. Customization service.

3. Online technical support.

4. Video inspection of machine before delivery

5. Video installation of machine

6. Reliable after sale service.

7. 18 months quality guarantee and life time technical assistance.

8. We can send engineeres to clients’ company for assistance.

9. All the assistance needed from clients.