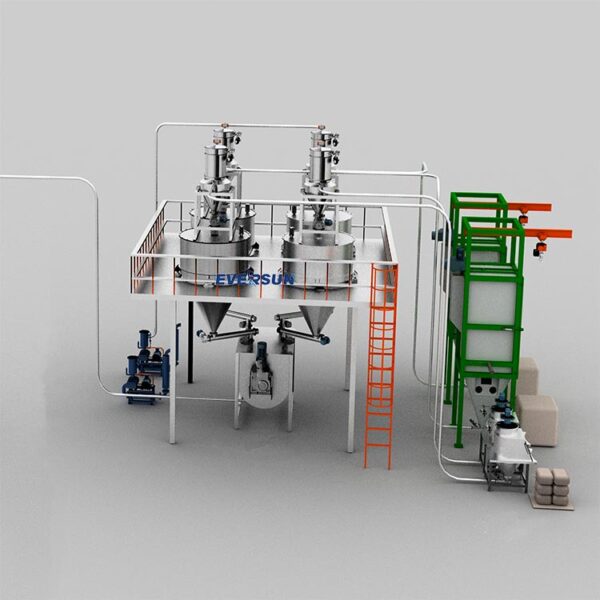

Weight and Batching System

The automatic weighing and batching system, also known as the automatic batching production line system, mainly performs batching according to the ratio by weight. It is composed of feeding stations or material storage bins, vacuum conveyors, weighing devices, mixing machines, packing machines, PLC controllers, and other components.

It can complete the automatic feeding and batching of a single material with a fixed weight or multiple materials with different formulas. It is widely used in petroleum, metallurgy, chemical, food, building materials, grain and oil, feed, plastic, agricultural and other products in the production process of ingredients.

- Description

- Inquiry

System structure

EVERSUN weigh batching systems is a comprehensive automation system that integrates microcomputer control and data management through weighing and feeding, formula control, mixing and homogenization, material transportation, and other processes. It uses Mitsubishi or Siemens series PLC and industrial control microcomputer to form a high-performance control platform. The system can satisfy the automatic operation of enterprise production control and help enterprises improve production efficiency.

Composition of ingredient weight batching

Feeding part: Use bulk bag discharger or bag dump station to unpack and unload bulk materials

Conveying part: use vacuum feeding to convey the material to each material storage silo with weighing module

Mixing part: According to material mixing and customer requirements, related mixing equipment is configured for mixing various materials.

Packaging part: According to material mixing and customer requirements, configure relevant packaging equipment for packaging mixed materials.

Automated weighing and batching systems workflow

Automated weighing and batching systems workflow

After the operator clicks the batching operation process to start, the material is fed through the bulk bag discharger or bag dump station, and then transported to the weighing hopper through the vacuum conveyor. Compared with the set target value, stop feeding when the set weight is reached, and then start the feeding process of the second material, repeat this way to two, three,…, until all the materials are fed. After the feeding is finished, the discharging pneumatic valve will open, and the mixture will flow out naturally under the action of gravity. After the feeding is completed, the discharging valve will be closed, and then enter the mixing process, after the material is mixed, it will be transported to the packaging machine, and finally, the packaging of the ingredients is finally completed.

EVERSUN Machinery focuses on providing integrated automation, process, and control systems for chemical, food, pharmaceutical, mining, and other industries. For more than 20 years, EVERSUN has been committed to providing effective, efficient, and reliable systems to global customers. The projects we serve are all over the world, helping many customers set up their production lines and providing them with solutions.