Product Introduction

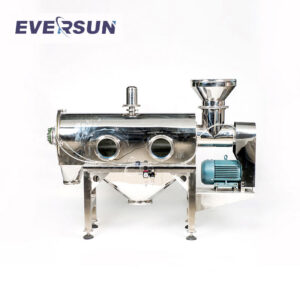

The EVERSUN linear vibrating screener is composed of two vibration motors, a sieve box, a screen mesh, a vibration absorbing body and a vibration damping device. The excellent horizontal motors are used as the power source to make the material be sifted on the screen while moving forward in a straight line. It can be equipped with single or multi-layer screens to achieve grading, impurity removal, powder removal, inspection, washing, dehydration and other purposes.

Working Principle

The material enters the feed port of the sieve machine uniformly from the feeder, and several grading products are produced through the multi-layer screens. Different grading materials are respectively discharged from the respective outlets.

The EVERSUN linear vibrating screener is a double vibration motor drive. The axis of two motors have an inclination angle with respect to the screen surface. When the two vibrating motors are synchronized and reversely operated, the exciting forces generated by the eccentric blocks cancel each other in a direction parallel to the motor axis, and are combined in a direction perpendicular to the motor axis. The motion trace of materials on the screen is a parabolic motion of the straight line forward. Under the combined force of the excitation force and the material self-gravity, the material is thrown up and jumped forward on the screen surface to linearly move, thereby achieving the purpose of screening and classifying the materials.

Application Industries: Powder, Granules, Bulk Solids, Liquid and other ingredients

(Materials below are just parts of our material list,for complete list,please consult us)

- Chemical industry: resin pigment, medicine, grease, paint, palette, cosmetic, etc.

- Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc.

- Metallurgy industry: aluminum powder, lead powder, copper powder, ore, alloy powder ,electrode powder, manganese dioxide, electrolytic copper powder, electric magnetic material, polishing powder, refractory material, etc.

- Mining industry: kaolin, alumina, carbon, quartz sand,titanium oxide, zinc oxide, etc.

- Abrasive material and ceramic industry: building sand, mica, alumina, abrasive,refractory material, slurry, etc.

- Mechanical industry: casting sand, powder metallurgy, electromagnetic material and metal powder, etc.

- Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

- Pollution treatment: waste oil, waste water,additives, activated carbon,etc.