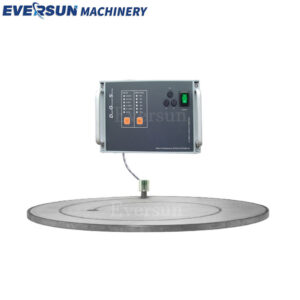

High Frequency Vibro Sifter

- Layer:1-2

- Product type: Automatic

- Diameter of screen(mm):330-1800

- Sieving precision:≤500 mesh or ≥0.028mm

- Power(KW):18-2.2

- Customize service:All parts can be customized

- Application:creamic, slurry, grain, pharmacy, beverage, chemcial, etc.

- Price(USD):1500-6500

- Description

- Inquiry

Production Introduction

For the efficient sieving of slurry materials, after years of practice and research, the EVERSUN group develop the high-frequency vibro sifter to solve the problems during the sieving process. So that the high capacity can be guaranteed while sieving precision can be assured.

The high-frequency vibro sifter destroys the tension of the slurry surface by high-frequency vibration and increases the high-speed oscillation of the fine-grained material on the sieve surface, accelerates the large-density (specific gravity) useful materials and separation, and increases the percentage of undersized fine materials touching the sieve. So that, the capacity can be increased sharply.

Features & Advantages

Features & Advantages

1. Unique design of the vibro sifter is one perfect choice for high-capacity separation of slurry.

2. Simple and easy-to-use structure, small size, lightweight, convenient installation and movement, easy maintenance and long service life.

3. Low energy consumption, high efficiency, compared with similar models, energy consumption can be reduced by half and production can be doubled.

4. High screening accuracy, screening particle size can reach more than 400 mesh, a wide range of use, any powder, grain, mucus can be applied.

5. The amplitude is small, the frequency is high, can reach 3000 / min, the screening effect of fine-grained, high-viscosity materials is more obvious, the effect is better.

6. Unique screen structure, loading network is convenient and fast, 3 to 5 minutes can be installed.

We offer customized services for high-frequency Vibro Sifter

EVERSUN is a professional manufacturer of screening equipment, that can provide you with customized services, and support OEM, and ODM customization. At the same time, EVERSUN can also design production lines and provide solutions for you.

1. We support different types of high-frequency screen customization, such as edged type, open type, heightened frame screen type, closed upper cover row, butterfly upper cover row, and bottom barrel shape.

2. The high-frequency pulp screen can add wheels, it is convenient for it to move in different positions.

3. Its screen mesh can be selected by customers according to their needs. Commonly used are 80 mesh, 120 mesh, 160 mesh, 180 mesh, 200 mesh, 220 mesh, 300 mesh, etc.

4. The high-frequency vibrating screen can be used Add a baffle plate to speed up the discharge and improve the screening efficiency.

5. The machine supports non-standard customization and can produce the machine for you according to your drawings.

6. The material of the machine is available in various types, such as stainless steel 304, stainless steel 316L, and carbon steel.