HOT PRODUCTS

-

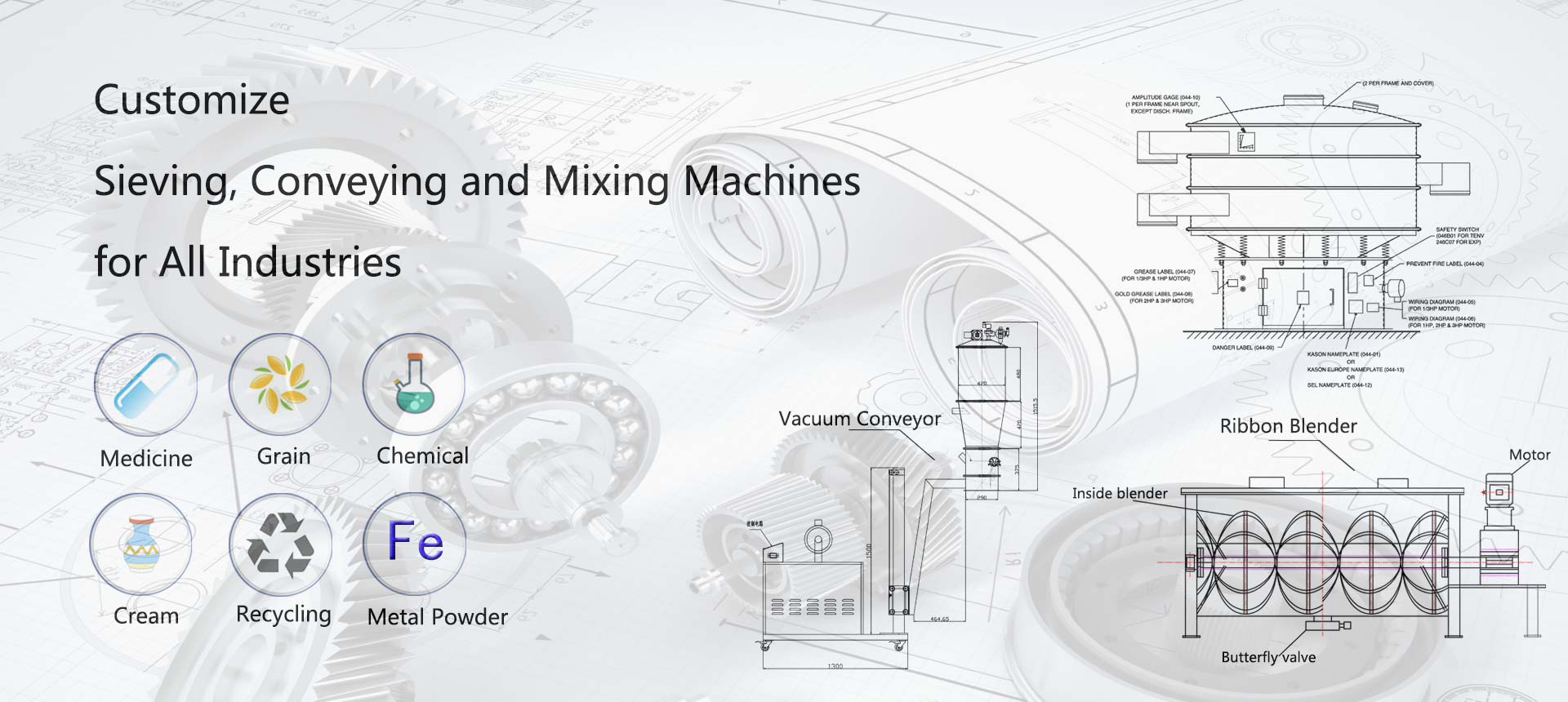

Vibro Sifter Machine

- Diameter of screen(mm): 330-1800

- Sieving precision: ≤500 mesh or ≥0.028mm

- Layer: 1-5

- Power(KW): 0.25-3

- Product type: Automatic

- Structure material option:316L stainless steel, 304 stainless steel, carbon steel.

- Customize service: All parts can be customized

- Price (USD): 1000-7000

- Application: Powder, Granules, Liquid, Bulk Solids and other ingredients.

-

Bulk Bag Unloader(Spout type bag)

- Unloadinging Capacity: 0.3~2 tons per bag

- Product type: Automatic

- Control system: HIM touch screen

- Product dimension: Customized

- Structure material option: Carbon steel, 304 stainless steel, 316 stainless steel

- Feature: Bag flap system, bag clamp system, weight system, PCL connection.,etc

- Customize service: All parts can be customized

- Price: USD5000~20000

-

Vacuum conveyor

Conveying Capacity: up to 10t/per hour

Conveying distance: up to 50m

Power(KW): 1.5-11

Product type: Automatic

Structure material option:316L stainless steel, 304 stainless steel

Customize service: All parts can be customized

Application: Powder, Granules, Bulk Solids and other ingredients. -

Ribbon Blender

Mixing barrel volume(L): 300 to 8000 or customized

Construction materials: Carbon steel, SUS304/316

Additional functions: Adjustable mixing speed, Mixing time regulation

Customized configuration: Spray system, heating system and cooling system

Mixing loading weight(KGS): Based on different models

Machine weight(KGS): Based on different models

Adjustable frequency(RPM): 0 to 33

Power(KW): 3 to 37

Price range(USD): 4000 – 30000 -

Tumbler Screening Machine

- Layer: 1-5

- Diameter of screen(mm): 600-2600

- Sieving precision: ≤500 mesh or ≥0.028mm

- Custmoized service: All parts can be customized

- Structure material option:316L stainless steel, 304 stainless steel, carbon steel

- Price(USD): 4500-28000

- Application: Powder, Granules, Liquid, Bulk Solids and other ingredients.

-

Rectangular Gyratory Sifter

- Standard Screening Area: 3.6~7.2m2

- Layer: 1-5

- Power(KW): 3~7.5

- Rotation Frequency: 180~260 r/min

- Structure material option:304 stainless steel, carbon steel.

- Customize service: All parts can be customized

- Certification: ISO, CE

- Application: Powder, Granules, Liquid, Bulk Solids and other ingredients.

-

Bag Dumping Station

- Size of damping station(mm): Customized

- Working Air Pressure(MPA): 0.6~1.5

- Power(KW): Based on different Model

- Product type: Automatic

- Structure material option:316L stainless steel, 304 stainless steel, carbon steel.

- Customize service: All parts can be customized

- Application: Powder, Granules, Bulk Solids and other ingredients.

-

Bulk Bag Discharger (Bottom closure type bag)

- Unloadinging Capacity: 0.3~2 tons per bag

- Product type: Automatic

- Control system: HIM touch screen

- Product dimension: Customized

- Structure material option: Carbon steel, 304 stainless steel, 316 stainless steel

- Feature: Bag flap system, bag clamp system, weight system, PCL connection.,etc

- Customize service: All parts can be customized

- Price: USD5000~20000

-

Linear Vibrating Screen

- Layer: 1-5

- Product type: Automatic

- Width(mm): 500-2200

- Length(mm): 2000-6000

- Sieving precision: ≤500 mesh or ≥0.028mm

- Power(KW): 2*(0.4-3.7)

- Structure material:316L stainless steel, 304 stainless steel, carbon steel.

- Customize service:All parts can be customized

- Price(USD): 1800-20000

- Application: Powder, Granules, Liquid, Bulk Solids and other ingredients.

-

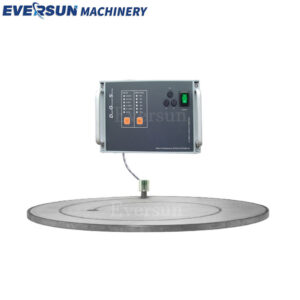

Ultrasonic Vibrating Sieve Machine

- Diameter of screen(mm): 330-1800

- Sieving precision: ≤500 mesh or ≥0.028mm

- Layer: 1-5

- Power(KW): 0.25-3

- Product Type:Automatic

- Structure material option:316L stainless steel, 304 stainless steel, carbon steel.

- Service:Customized machine can be available

- Price(USD): 2000-9000

- Application: Powder, Granules, Liquid, Bulk Solids and other ingredients.

-

Three-dimensional Mixer

- Mixing barrel volume(L): 2 to 2000

- Mixing loading weight(KGS): Based on different model

- Machine weight(KGS): 15 to 1700

- Adjustable frequency(RPM): 3 to 17

- Power(KW): 0.18 to 15

- Price range(USD): 2000 – 30000

-

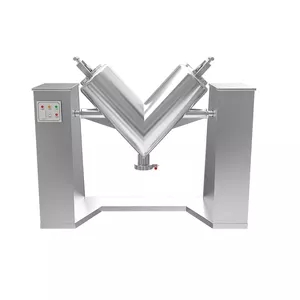

V Type Mixer Machine

Mixing barrel volume(L): 2 to 8000

Mixing loading weight(KGS): Based on different model

Machine weight(KGS): 15 to 1700

Adjustable frequency(RPM): 3 to 17

Power(KW): 0.09 to 15

Price range(USD): 2000 – 30000

Want to find the most suitable sieving machine? Contact us today!

EVERSUN Machinery Manufacturing Co., Ltd. is a professional manufacturer and supplier of machinery equipment in China. The scale of our company is relatively large, covering an area of 18 mu. And we have about 200 employees. We specialize in services such as unpacking, unloading, crushing, screening, weighing, conveying, mixing, packaging, measuring, and storage of bulk materials. We have long been committed to providing comprehensive services such as consulting, research and development, design, manufacturing, installation, and after-sales for customers in many industries, such as chemical, food, pharmaceutical, environmental protection, and new energy.

We are committed to providing products with the best quality and service!

Our products mainly include the sieving machine, vacuum conveyor, ribbon blender, bulk bag unloader, bulk bag discharger, pulverizer, packing machine, etc. And they have passed ISO9000 certification, CE certification, and SGS certification. The main parts and accessories of our products are all internationally famous brands, including SKF, Ollie Wolong and ABB, Schneider, Siemens, SMC, Adech, and other international brands. In particular, the company has invested heavily in research and development of the dust-free conveying system. We have developed more than 100 sets of molds related to vacuum conveyors that meet national and industrial standards, ensuring the quality and stability of products. The production process adopts the modular modern design, standard 6S unified management, and strict zoning operation requirements are implemented for processing, inspection, debugging, and testing, greatly reducing the production cycle and costs of the product while increasing the product’s qualification rate.

Over the years, the company has integrated the actual experience of customers and combined its own advantages to provide customers with high-performance equipment, design feasible production lines and provide perfect solutions, which have been widely praised. So far, we have delivered excellent, innovative, and high-quality machinery and equipment to customers in more than 30 countries around the world.

- Application

Our machinery and equipment are widely used in pharmaceutical, food, chemical, metallurgy, mining, power plant, building materials, and other industries. We can produce the powder sieving machine, vacuum conveyor, bulk bag unloader, ribbon blender, and other equipment that meet the existing national and corresponding industry standards according to the requirements of different industries.

- Installation and commissioning

We will send professional technicians to guide the customer’s installation and commissioning. At the same time, we can also provide customers with mechanical diagrams, circuit diagrams, gas circuit diagrams, installation instructions, user manuals, and other documents to facilitate customer installation and commissioning.

We are committed to providing high-quality the powder sieving machine, particle sieving machine, slurry sieving machine, vacuum conveyor, ribbon blender, bulk bag unloader, bulk bag discharger, and other equipment to meet customers’ requirements for food, chemical, pharmaceutical, and mining, and other industries. If you are interested in our products or need a complete set of solutions, please feel free to contact us.

Featured clients we are serving