Bulk Bag Unloader Product Description

The bulk bag unloader is also called bulk bag discharge station. It is used for unloading and discharging of bulk bag, FIBC bag, jumbo bag, super sack, big bag for powder and granular materials. The bulk bag unloader can be divided into two types, normal type and explosion-proof type. Eversun bulk bag discharge station is widely used in food, chemical, pharmaceutical, plastic, lithium battery, new materials, and other industries. It is an efficient, safe, and dust-free bag unpacking equipment.

It can be connected to various equipment such as silo, screw conveyor, vacuum feeder, crusher, and other equipment to form an automated production line. Our engineers can provide one integrated solution according to customers’ application requirements.

EVERSUN is a professional manufacturer of bulk bag unloader, the machine we produce is a high degree of automation equipment, and the machine can be customized according to your needs. The hopper volume, dimensions, electric control system, weighing system, machine material etc. can be customized.

Normal type and explosion-proof type

Normal type and explosion-proof type

Bulk Bag Unloader Working Principle

Eversun bulk bag unloader lifts the bulk bags from the ground with the help of electric hoists or cranes/forklifts, then moves them to the top of the hopper, then closes the bag clamping valve, and then manually unfastens the bag mouth, and then allows the materials in the bags to flow smoothly by their own weight. The machine can also be supplemented with a bag-beating device to make the material in the bag flow into the hopper more smoothly. The bottom of the equipment can be connected to a small bag dumping station, vacuum conveyor, screw conveyor, and other equipment to transport the material to the designated location.

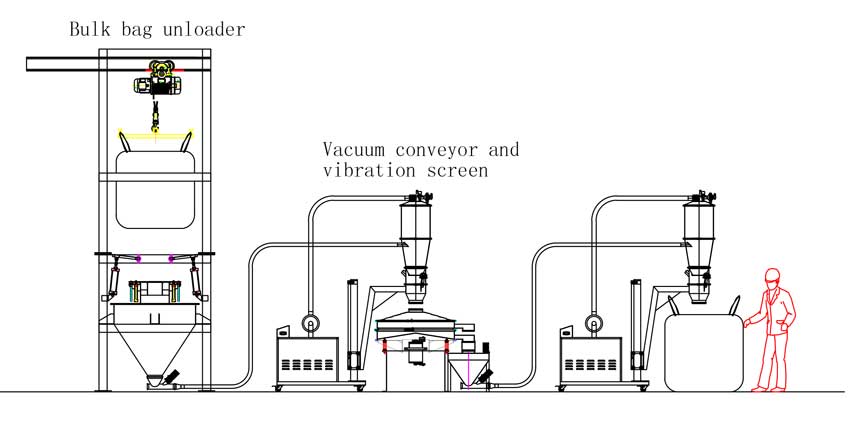

One bulk bag unloader production line for our American client

Bulk bag unload + Vacuum conveyor + Vibration screen + Vacuum conveyor + bags

Contact us today to design your own production line, free of charge!

Bulk Bag Unloader Product Advantages

Eversun bulk bag unloader has a open structure and easy operation, which can effectively reduce the labor intensity of workers and improve production efficiency. The bulk bag unloading system is equipped with a bag flapping device, which can crush agglomerated materials to ensure that the materials can enter the next process from the bag. The bulk bag discharge station is equipped with a dust removal interface, and a dust removal device can be installed to achieve a dust-free working environment. The equipment can be equipped with remote monitoring devices to realize remote control.