Product Introduction

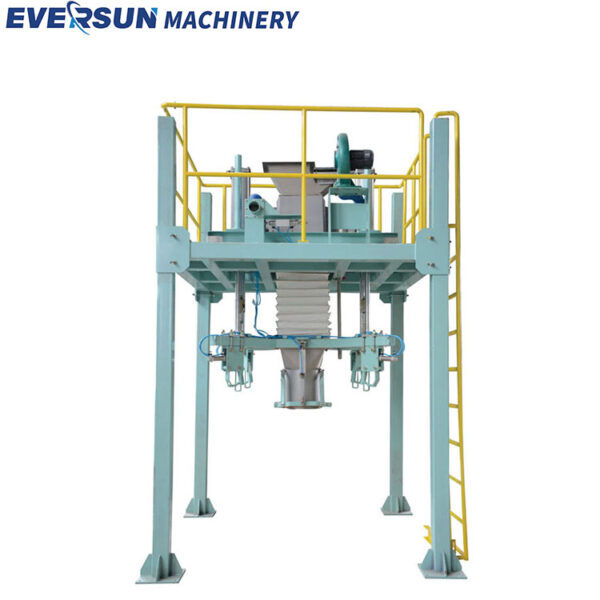

The bulk bag packing machine also called bulk bag filling machine, is suitable for quantitative packaging of powdery and granular materials with less moisture and better fluidity. It is widely used in grain, chemical, engineering plastics, fertilizer feed, building materials, and other industries. It can pack many types of bag, such as 1-2 ton bulk bag, FIBC bag, jumbo bag, super sack, big bag, etc. It can be directly connected to the front-end processing line to meet the requirements of large-scale, batch, and automated production and packaging.

The bulk bag loading system produced by EVERSUN adopts vibrating feeding (frequency conversion double-speed feeding), upper metering, and precision valves to achieve quantitative filling. The packaging process is controlled by a control cabinet, and other operations except bag hanging and bagging can be automatically completed by the program, so the machine is easy to operate and has a high degree of automation, which can greatly help you improve production efficiency.

The bulk bag packing machine produced by EVERSUN can be tailored for you according to the characteristics of the user’s specific materials and the requirements of the manufacturer, and we can also design non-standard products for you. At the same time, EVERSUN is also a supplier of quantitative packaging and palletizing solutions. We can design production lines and provide solutions for you.

Features & Benefits

1. The bulk bag filling equipment is mainly composed of guardrails, quantitative buckets, cylinders, hooks, entrainment nozzles, control cabinets, stepping motors, frames, belts, ladders, etc. Other components can be selected according to customer requirements.

2. The electric control system of the bulk bag filler is programmable, and the control process is very reliable.

3. Product accessories can be selected according to your needs. The default configuration is domestic and foreign brand components, such as Schneider and Siemens motors.

4. The weighing system of bulk bag filling systems adopts electronic scale platform scale measurement, which can be used for digital proofreading and parameter setting. It has functions such as weight accumulation display, automatic tare, automatic zero calibration, and automatic drop correction.

5. The instrument of the machine is equipped with a communication interface, which is convenient for online networking, and can carry out real-time monitoring and network management of the packaging machine.

6. The machine adopts multi-stage frequency conversion speed regulation and servo drive control, which can be adjusted and controlled according to the user’s requirements for packaging speed. , the performance of the equipment is stable, the packaging precision is high, and the speed is fast.

7. The machine is made of thickened steel, the surface is sprayed with plastic, and stainless steel is optional.