Conical Spiral Mixer

Volume:300~30000 L

Mixing Capacity: 100~15000 L

Mixing Time: 15~60 minutes

Power: 1.5~55kw

Construction Materials: 316L, SS304, Carbon Steel

Price: 2000~10000USD

- Description

- Inquiry

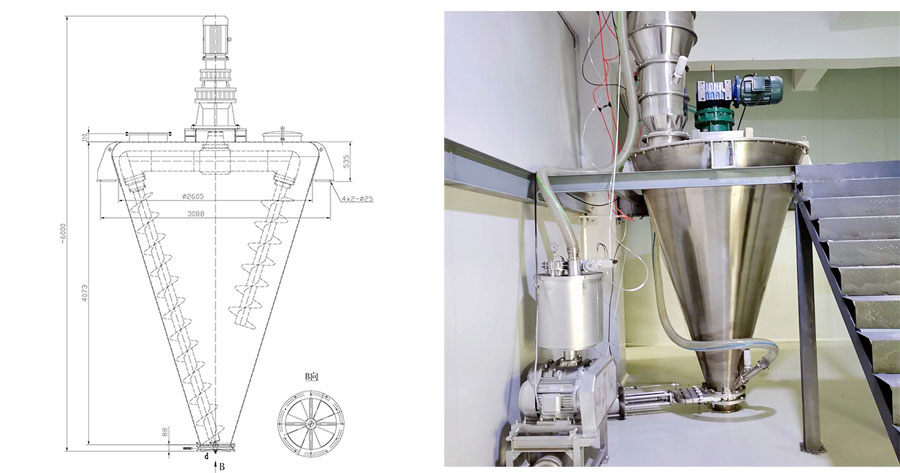

What is Conical Screw Mixer?

Conical screw mixer is a new type of high-efficiency and high-precision mixing equipment. Using the principle of combining the revolving motion and the rotating motion of two tapered screws, the materials with different specific densities in the mixer can reach the appropriate mixing degree. The mixing speed is rapid with excellent results.

It is widely used in various industries such as pharmaceuticals, food, chemicals, pesticides, feed, petroleum, metallurgical mines, fertilizers, coatings, pigments, dyes, additives, refractory materials, fine chemicals, new materials, electronic plastics, ceramics, building materials and powders of other industries.

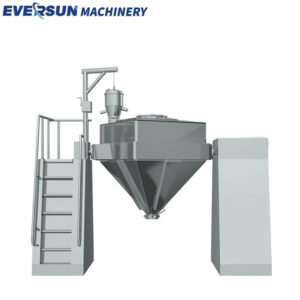

Conical Spiral Mixer with Vaccum Conveyor

Advantages of Conical Spiral Mixer

With many years of production experience, Eversun Machinery’s conical spiral conveyor has the following features:

- Reasonable structure, safe and reliable operation, the screw shaft has no bottom bearing, and the fault caused by the powder leakage of the bottom bearing is eliminated.

- The mixing speed is fast with uniform mixing quality. The double-tapered screws of this machine are arranged asymmetrically. The long and short screws expand the mixing range, so the contrast is very different, and the mixing ratio is suitable for mixing various

- The energy-saving effect is obvious, and the energy consumption of this machine is smaller than other kinds of mixers.

- The mixing process is gentle and the materials will not get pressed, wear, and overheating.

- The mixed formulation is stable, and no delamination or segregation occurs.

- Fully sealed and dust-free, simple operation and convenient maintenance with long service life.

Working Principle of Conical Spiral Mixer

The combination of the revolution and rotation of the screw in the mixer results in four flow forms of the powder, that is, the compound movement of convection, shear, diffusion, and infiltration. Therefore, powder materials can quickly achieve uniform mixing in this mixer.

Eversun Machinery has rich manufacturing experience and professional engineers. We will design suitable models for you to choose based on your needs. Please contact us to inform the materials you need to mix, the mixing capacity, and other information you think necessary, and we will customize a professional solution for you.