コニカルスパイラルミキサー

音量:300〜30000 L

混合能力: 100〜15000 L

混合時間: 15〜60分

力: 1.5〜55kw

建設資材: 316L, SS304, 炭素鋼

価格: 2000〜10000USD

- 説明

- 問い合わせ

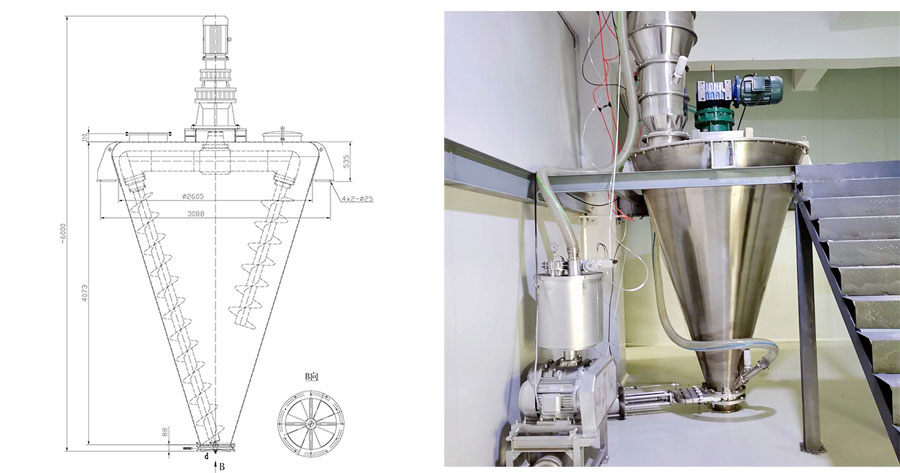

コニカルスクリューミキサーとは?

コニカルスクリューミキサーは、新しいタイプの高効率・高精度混合装置です。. 2本のテーパーねじの回転運動と回転運動を組み合わせる原理を使用, ミキサー内の比密度が異なる材料は、適切な混合度に達することができます。. 混合速度が速く、優れた結果が得られます.

医薬品など様々な産業で広く使用されています, 食物, 化学薬品, 農薬, フィード, 石油, 冶金鉱山, 肥料, コーティング, 顔料, 染料, 添加物, 耐火材料, ファインケミカル, 新素材, 電子プラスチック, セラミック, 他の産業の建築材料および粉.

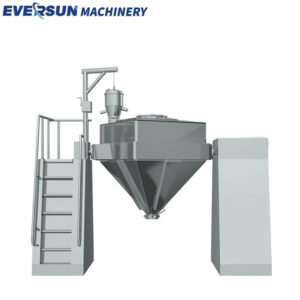

バキュームコンベア付きコニカルスパイラルミキサー

コニカルスパイラルミキサーのメリット

長年の生産経験を持つ, エバーサンマシナリーの円錐スパイラルコンベヤは以下の特長を持っています:

- リーズナブルな構造, 安全で信頼性の高い操作, スクリューシャフトにはボトムベアリングがありません, ボトムベアリングの粉体漏れによる故障を解消.

- 混合速度が速く、均一な混合品質. 本機のダブルテーパーネジは非対称に配置されています. 長いスクリューと短いスクリューは混合範囲を拡大します, コントラストが大きく異なります, 混合比は様々な混合に適しています

- 省エネ効果は一目瞭然, この機械のエネルギー消費量は他の種類のミキサーよりも小さいです.

- 混合プロセスは穏やかで、材料はプレスされません, 切る, と過熱.

- 混合製剤は安定しています, 層間剥離や分離は発生しません.

- 完全に密閉され、ほこりがない, シンプルな操作と便利なメンテナンスで長寿命を実現.

コニカルスパイラルミキサーの動作原理

ミキサー内のスクリューの回転と回転の組み合わせにより、4つの流動形態の粉末が得られます。, あれは, 対流の複合運動, 剪断, 拡散, と浸透. したがって, 粉末材料は、このミキサーで迅速に均一な混合を実現できます.

Eversun Machineryは、豊富な製造経験とプロのエンジニアを擁しています. お客様のニーズに基づいて適切なモデルを設計します。. 混合する必要のある材料については、お問い合わせください, 混合能力, その他必要と思われる情報, そして私たちはあなたのためにプロのソリューションをカスタマイズします.