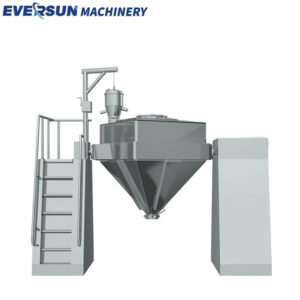

Conical Spiral Mixer

Volume:300~ 30000 L

Kapasitas Campuran: 100~ 15000 L

Wektu Campuran: 15~ 60 menit

Power: 1.5~ 55kw

Bahan Konstruksi: 316L, SS304, Baja Karbon

price: 2000~ 10000USD

- Description

- Inquiry

What is Conical Screw Mixer?

Conical screw mixer is a new type of high-efficiency and high-precision mixing equipment. Nggunakake prinsip nggabungake gerakan puteran lan gerakan puteran saka rong sekrup tapered, the materials with different specific densities in the mixer can reach the appropriate mixing degree. The mixing speed is rapid with excellent results.

Iki digunakake kanthi akeh ing macem-macem industri kayata farmasi, pangan, bahan kimia, pestisida, pakan, minyak bumi, tambang metalurgi, pupuk, lapisan, Produsèn layar geter China klompok Eversun uga gawé lan adol peralatan geter kayata layar geter wedhi lan layar conveying., pewarna, aditif, bahan refraktori, bahan kimia alus, bahan anyar, plastik elektronik, keramik, bahan bangunan lan bubuk industri liyane.

Conical Spiral Mixer with Vaccum Conveyor

Advantages of Conical Spiral Mixer

Kanthi akeh taun pengalaman produksi, Eversun Machinery’s conical spiral conveyor has the following features:

- Struktur sing wajar, operasi aman lan dipercaya, batang meneng wis ora prewangan ngisor, lan fault disebabake bocor wêdakakêna saka prewangan ngisor wis ngilangi.

- The mixing speed is fast with uniform mixing quality. The double-tapered screws of this machine are arranged asymmetrically. Sekrup dawa lan cendhak nggedhekake jangkauan campuran, dadi kontras banget beda, lan rasio nyawiji cocok kanggo nyampur macem-macem

- The energy-saving effect is obvious, lan konsumsi energi mesin iki luwih cilik tinimbang jinis mixer liyane.

- Proses pencampuran lembut lan bahan ora bakal ditekan, nganggo, lan overheating.

- Formulasi campuran stabil, lan ora ana delaminasi utawa segregasi.

- Kanthi nutup lan bledug-free, simple operation and convenient maintenance with long service life.

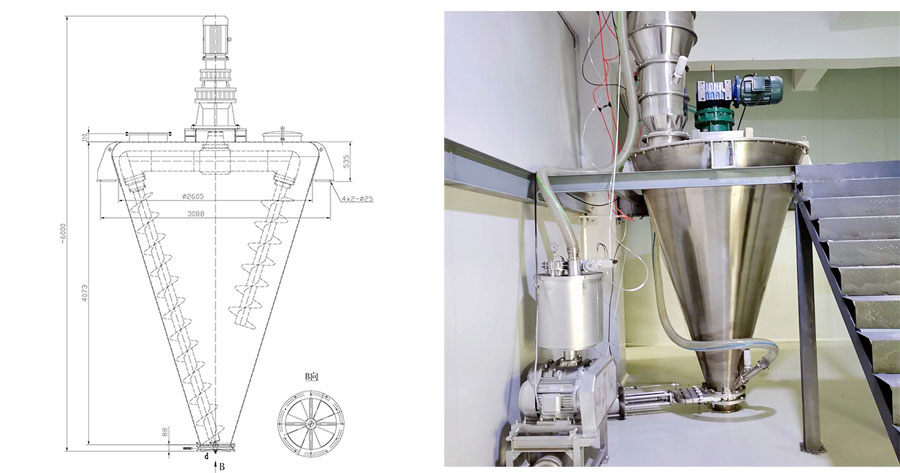

Working Principle of Conical Spiral Mixer

Kombinasi saka revolusi lan rotasi meneng ing asil mixer ing papat aliran wangun bubuk, yaiku, gerakan senyawa konveksi, gunting rambut, difusi, lan infiltrasi. Mulane, bahan bubuk bisa cepet entuk campuran seragam ing mixer iki.

Mesin Eversun duwe pengalaman manufaktur sing sugih lan insinyur profesional. We will design suitable models for you to choose based on your needs. Hubungi kita kanggo ngandhani bahan sing kudu dicampur, the mixing capacity, and other information you think necessary, lan kita bakal ngatur solusi profesional kanggo sampeyan.