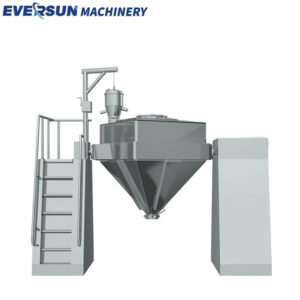

원추형 나선형 믹서

용량:300~ 30000 L

혼합 용량: 100~ 15000L

혼합 시간: 15~ 60 분

힘: 1.5~ 55kw

건축 자재: 316L, SS304, 탄소강

가격: 2000~ 10000 달러

- 설명

- 문의

원추형 스크류 믹서 란??

원추형 스크류 믹서는 새로운 유형의 고효율 및 고정밀 혼합 장비입니다.. 두 개의 테이퍼 나사의 회전 운동과 회전 운동을 결합하는 원리 사용, 믹서의 특정 밀도가 다른 재료는 적절한 혼합 정도에 도달할 수 있습니다.. 우수한 결과로 혼합 속도가 빠릅니다..

제약 등 다양한 산업에서 널리 사용됩니다., 음식, 화학, 살충제, 밥을 먹이다, 석유, 야금 광산, 비료, 코팅, 안료, 염료, 백색 비료 과립 황산 암모늄, 내화물, 정밀 화학, 신소재, 전자 플라스틱, 세라믹, 다른 산업의 건축 자재 및 분말.

진공 컨베이어가 있는 원추형 스파이럴 믹서

원추형 스파이럴 믹서의 장점

다년간의 생산 경험, Eversun Machinery의 원추형 나선형 컨베이어에는 다음과 같은 기능이 있습니다.:

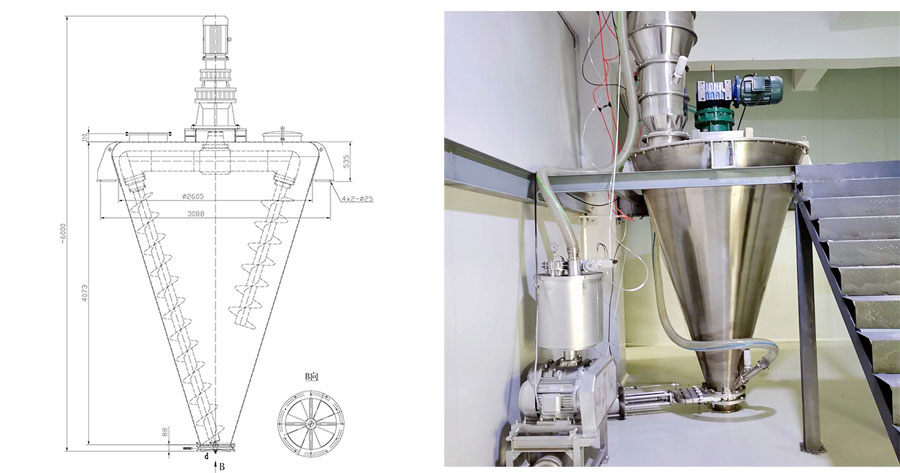

- 합리적인 구조, 안전하고 안정적인 작동, 나사 축에는 바닥 베어링이 없습니다., 바닥 베어링의 분말 누출로 인한 결함이 제거됩니다..

- 균일한 혼합 품질로 혼합 속도가 빠름. 이 기계의 이중 테이퍼 나사는 비대칭으로 배열됩니다.. 길고 짧은 나사는 혼합 범위를 확장합니다., 그래서 대비가 매우 다릅니다, 혼합 비율은 다양한 혼합에 적합합니다.

- 에너지 절약 효과는 분명합니다, 이 기계의 에너지 소비는 다른 종류의 믹서보다 적습니다..

- 혼합 과정이 부드럽고 재료가 눌리지 않습니다., 입고 있다, 과열.

- 혼합 제형은 안정적입니다., 박리 또는 분리가 발생하지 않습니다..

- 완전히 밀봉되고 먼지가 없음, 긴 서비스 수명으로 간단한 작동 및 편리한 유지 보수.

원추형 나선형 믹서의 작동 원리

믹서에서 스크류의 회전과 회전의 조합으로 4 가지 흐름 형태의 분말이 생성됩니다., 그건, 대류의 복합 운동, 전단, 확산, 및 침투. 따라서, 분말 재료는이 믹서에서 균일 한 혼합을 빠르게 달성 할 수 있습니다..

Eversun Machinery는 풍부한 제조 경험과 전문 엔지니어를 보유하고 있습니다.. 우리는 귀하의 필요에 따라 선택할 수 있는 적합한 모델을 설계할 것입니다.. 혼합해야 할 재료를 알려주려면 당사에 문의하십시오., 혼합 용량, 및 귀하가 필요하다고 생각하는 기타 정보, 그리고 우리는 당신을 위해 전문 솔루션을 사용자 정의 할 것입니다.