The double cone mixer with a stirrer is a commonly used mixing equipment used to mix and homogenize powdery or granular materials. It combines the functions of a double-cone mixer and a stirrer to further improve the mixing effect during the mixing process.

A double-cone... read more

Weighing silo can play a variety of roles on a production line.

First of all, the weighing silo can weigh and measure materials with high precision to ensure the accurate proportion of materials, which is very important for the control and quality control of materials... read more

Vibrating screen feeding method

1. Manual feeding

Manual feeding is the manually shoveling material directly into the vibrating screen inlet. If uniform feeding of the vibrating screen is to be achieved, manual feeding needs to be abandoned.

2. Conveyor feeding

Use screw conveyors, vacuum feeders, belt conveyors, and... read more

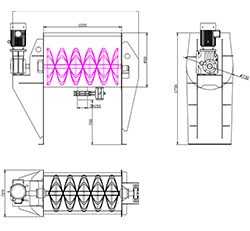

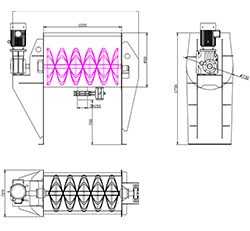

Horizontal Ribbon Mixer structure characteristics

1, the machine is a horizontal cylinder, inside and outside the two-layer spiral belt has a unique structure, smooth running, reliable quality, low noise, long service life, easy installation and maintenance, and a variety of mixer structures, versatile mixing equipment.... read more

vacuum feeding machine is a dust-free closed pipeline conveying equipment that transmits particles and powdery materials by means of vacuum suction and uses the pressure difference between vacuum and environmental space to form gas flow in the pipeline, driving the movement of powdery materials,... read more

When some factories use screening equipment, they still use the original manual feeding method, causing the dust to fly, which is laborious and inefficient. In order to change the production environment, a food factory in Saudi Arabia found the manufacturer of EVERSUN Machinery and... read more

The pneumatic grain suction machine is an efficient agricultural machinery and equipment that is widely used in grain harvesting, transportation, and storage in agricultural production. It uses powerful airflow to suck grain into the machine quickly and efficiently, and transport the grain to centralized... read more

1. Pre-installation preparation

Before installing the vibrating screen counterweight, some pre-installation preparations are required.

(1) First determine the model and specifications of the vibrating screen, and select the number of counterweight blocks to be installed according to the actual situation.

(2) Prepare the required counterweights and installation... read more

Small bag feeding station is mainly used to put 25-60kg sachets of materials, is used in various industries, in some special workshops, the requirements of dust-proof is higher, you can use EVERSUN customized machine.

The hydraulic lifting door of the small bag feeding station is equipped with... read more

Application of pneumatic vacuum feeder in the pharmaceutical industry

The requirements of the pharmaceutical production process are very strict, and the materials must be kept clean to prevent contamination and foreign matter from entering. Eversun pneumatic vacuum feeder generates compressed air through a vacuum generator, using... read more