What is Rotary valve?

The rotary valve is also called unloader, airlock valve. It is an important equipment for hopper silo, pneumatic conveyer and ventilation dust removal system. The rotary valves are divided into three categories: common type, pressure-resistant type, and high-temperature resistant type. The main purpose is to continuously discharge the materials in the unloader or dust discharge equipment, and at the same time, it can ensure that the pressure inside the equipment is not exposed to the normal pressure environment. Because of its working characteristics, it is widely used in milling, feed, machinery, the chemical industry, металлургия, цемент, and many other fields. For powdery, granular, хлопь, and fibrous materials under positive pressure and negative pressure, it plays the role of continuous discharge and air tightness.

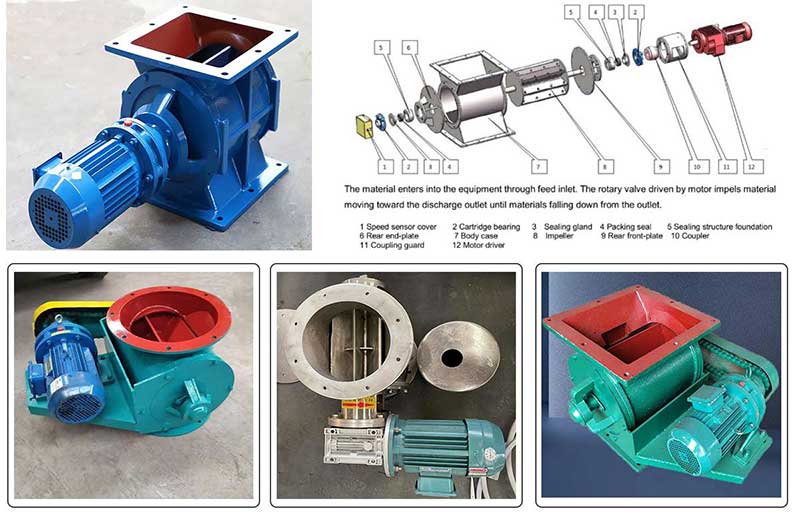

The inlet and outlet of the rotary valve are square or circular, with feeding from the upper part and discharging from the lower part.

Features and Advantages of Rotary valve

- The rotary valve has a compact structure, a beautiful appearance, and is easy to use.

- The rotary valve runs smoothly with low noise.

- Since the bearing and gearbox are a certain distance away from the housing when the fan is turned off, the high temperature and lubrication are greatly improved.

- The rotary valve in our factory can also be designed and manufactured according to user requirements. (Bracket coupling belt chain drive)

- Equipped with a reducer, the structure is reliable, stable, and compact.

- The elastic impeller is used to enhance the flexible seal to eliminate the phenomenon of impeller jamming.

Working principle of Rotary valve

The rotary valve is an improved impeller open-type rotary valve. Its structure is a pull-out mechanism composed of an impeller, a casing, an end cover, a bearing, a plexiglass cylinder (with or without), and other components. Its upper end has flange, the flange is connected to the discharge port of the unloader, accepts the material discharged from the unloader, and discharges the material from the bottom during the continuous rotation of the impeller. The impeller adopts an open type, which not only plays the role of preventing blockage, but also reduces the weight of the machine and reduces appearance.