Rotary dryer

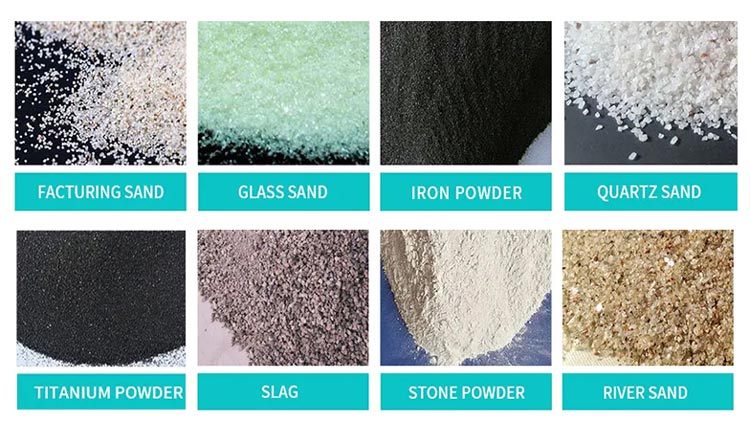

Application materials:

river sand, quartz sand, coal, ore powder, clay, sawdust, feed, rice husk, grain ,slag and so on

Capacity: 1~30 tons per hour or customized

Final moisture: ≤1% or adjustable

Power Supply: 220V~480V or customized

- Description

- Inquiry

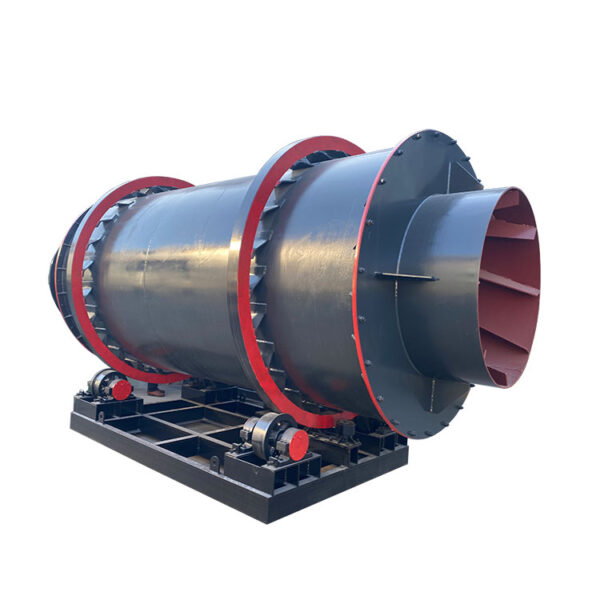

Introduction of rotary dryer

Rotary dryer is an advanced drying equipment with large output and high efficiency. Rotary dryer is also called as three-cylinder dryer, the body of the dryer is composed of concentric barrels of different diameters, which are nested and assembled in accordance with professional mechanical structure design principles.

During the entire drying process, the three-cylinder body structure effectively increases the heat exchange area, fully utilizes thermal energy, and greatly reduces heat dissipation loss, thus reducing the energy consumption of the dryer.

Rotary dryer can use a variety of fuels such as oil, gas, coal, biomass, странице, and is widely used in construction, chemical industry, сола хозяйство, mining and other industries to process river sand, quartz sand, coal, ore powder, clay, sawdust, feed, rice husk, grain , medicinal materials and other types of lump, granular, powdered materials.

Parts of processing materials

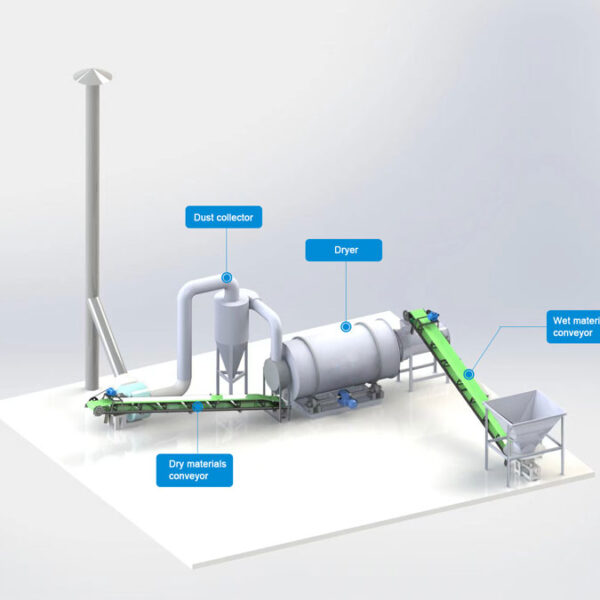

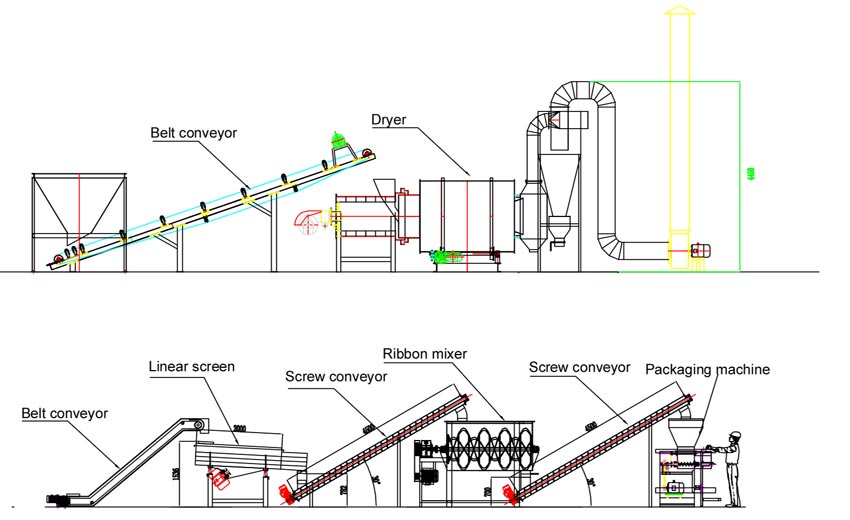

Typical application of rotary dryer

sand drying and packing production line

Sand drying——sifting——mixing——storing——packing

Features of rotary dryer

- Make full use of thermal energy and effectively reduce energy consumption, with thermal energy efficiency up to 95%. Compared with other dryers with the same output, the occupied area is reduced by about 50%, effectively saving investment.

- The equipment uses manganese steel as the raw material for production, which has excellent heat resistance and wear resistance, ensuring long service life and reducing maintenance costs.

- The barrel body has less heat dissipation loss and can be directly connected to dust removal equipment.

- It is not limited by energy and can use oil, gas, coal, biomass and other fuels.

- Humidity can be flexibly adjusted according to needs, and the minimum can reach ≤1%.

How to buy one rotary dryer

Please contact our professional engineers, we will select the appropriate model based on the material, humidity, output and other information you provide, and produce corresponding design drawings for your reference, free of charge.

Related Products

-

Sand and coal dryer

Size: тури

Rotate speed: 5-2.09 rpm

Capacity: 2~46 tons/h or customized

Куатан: 11-400КВт

Inclination angle: 1.8-2.5°

Application materials: sand, quartz sand, coal, ore, sawdust, grain, slag, странице