Gyratory Vibrating Screen

- Width(ммш): 1200-2000

- Length(ммш): 2400-4000

- Ару шакта: ≤350 mesh or ≥0.028mm

- Ланзывлӓм: 1-3

- Куатан(КВт): 5.5-7.5

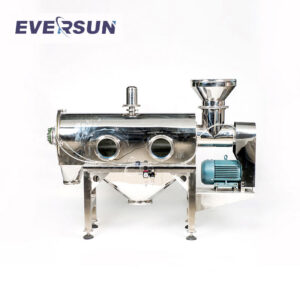

- Product type: Автоматический, Rotex type gyratory screener

- Structure material option: 316L stainless steel, 304 ӹрдӓнгдӹмӹ вурс, carbon steel.

- Customize service: All parts can be customized

- Ӓкшӹ(Доллареш США): 8000-30000

- Description

- Inquiry

Кычылтмаш Продукция

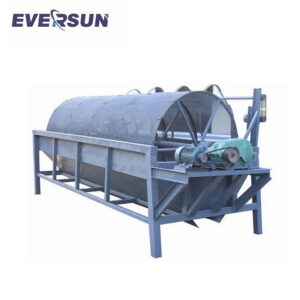

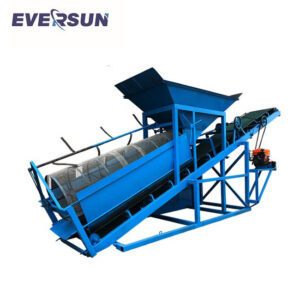

Gyratory vibrating screen can also be called as rotex type screener, it is one kind of rotex type gyratory screener. It can realize high capacity sieving output from tens to hundreds of tons . It is mainly used for rubber powder, grain, sugar, plastic, mine and other industries. With the unique engineering structure,the gyratory vibrating screen use giant screen area and three-step sieving motion to realize one screening process of high output and accuracy.

The first step is gyratory motion. This will happen at the feed side of gyratory vibrating screen, the materials will spread across the sieve rapidly and go forward with stratification.

The second step is elliptical motion. When the materials come to the central area of sieve, they will do elliptical movement. During this process, the materials will get efficiently stratified and move forward.

The third step is reciprocating motion. The materials continue to go through efficient stratification until arrival the discharge end. During the entire sieving process, the materials are always touching the screen surface.

Three-step Sieving Motion of Gyratory Vibrating Screen

Характеристикыжы дӓ яжо:

1.Big output capacity with high precision—— The gyratory vibration screen is one kind of rotex screener, it is designed to realize big output capacity for various use conditions.

2.Fully enclosed without leak —— the unique design of machine structure makes sure no leak happen during the sieving process, so that no materials will be wasted and no pollution will happen.

3.No damage to materials —— the materials will use normal motor instead of vibration motor to do circulation of sieving on the screen surface. So that the materials will not get any outside physical strength and no damage will happen to the materials.

4.Convenient Inspection—— the worker can easily check the material condition during sieving process, so that the entire working condition can be controlled.

How to Choose the Suitable Gyratory Vibrating Screen

Our experienced engineers will have detailed communication with clients to fully understand the their needs. Then based on those information, such as material feature, target capacity, and use condition, they will design the suitable model of gyratory vibrating screen for clients’ checking. Before final shipment, the inspection images and videos will be made and provided for clients’ confirmation, or we can even present online live broadcast to show the machine. After everything confirmed, the gyratory vibrating screen will be shipped to the clients.