桶等粉状物料需要..

在申请期间 我什么, 桶等粉状物料需要.., 桶等粉状物料需要..?

停机检查的必要性 我什么 从五个方面入手:桶等粉状物料需要..,作业结束时最好不要改变节奏. 仔细清理机舱内杂物,防止杂物造成的隐患。保持筛机运行方式静止,尽量不要沾染灰尘。不要将与其无关的设备放置在屏幕的各个侧面.

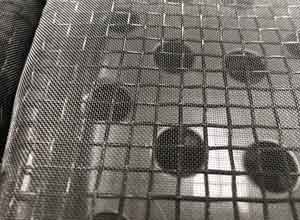

影响加工强度的两大因素 我什么 为筛面活动方式,筛面结构参数与筛面上料层松散度及速度目标有关, 频率, ETC. 需要通过筛网的细粒物料相对于筛面的比例. 所以,分层筛分过程中筛面组织参数可分为筛面尺寸的影响和尺寸的影响, 筛孔形状及开孔率.

影响加工强度的两大因素 我什么 为筛面活动方式,筛面结构参数与筛面上料层松散度及速度目标有关, 频率, ETC. 需要通过筛网的细粒物料相对于筛面的比例. 所以,分层筛分过程中筛面组织参数可分为筛面尺寸的影响和尺寸的影响, 筛孔形状及开孔率.

在正常情况下, 筛面直径决定筛子的处理能力. 屏幕面积越大, 处理能力越大; 筛面尺寸决定了筛网的筛分效率. 屏幕面积越大, 效率越高. 筛孔越大, 单位筛面积的处理能力越高,筛分效率越高。筛孔的大小取决于筛分目的和要求。对于粒径较大的常规筛分, 筛孔尺寸通常等于筛分粒度; 然而, when the required sieve particle size is small, the sieve hole should be slightly larger than the sieve particle size; for approximate sieve, the sieve hole is much larger than the sieve particle size.

EVERSUN机械 (河南)有限公司,.有限公司成立于 2003, EVERSN Machinery是筛分和输送设备的专业制造商, 产品质量体系已通过ISO9001严格认证:2005 和CE国家标准.

我们的主要产品是筛分机, 振动筛机, 超声波筛分机, 真空输送机, 倾销站, 滚筒筛分机, 工业筛分机, 液体过滤, 矩形回旋筛, 螺旋输送机等.

EVERSUN 机械提供了一个 4 层滚筒筛分机的解决方案.

销售部: Sales@vibrosievingmachine.com, Cell/WhatsApp:+86 13162301696