Rotex Screener

- Width(ммш): 1200-2000

- Length(ммш): 2400-4000

- Ару шакта: ≤350 mesh or ≥0.028mm

- Ланзывлӓм: 1-3

- Куатан(КВт): 5.5-7.5

- Product type: Автоматический,

- Structure material option: 316L stainless steel, 304 ӹрдӓнгдӹмӹ вурс, carbon steel.

- Customize service: All parts can be customized

- Ӓкшӹ(Доллареш США): 8000-30000

- Description

- Inquiry

Кычылтмаш Продукция

Rotex screener is one big output sieving machine with high precision. With very big screening area and unique three-step sieving, it is one idea sieving machine for the screening of granular materials in industrial mass production. Spherical, strip, хлопь, column, fragile, irregularly shaped materials can be screened with high precision and huge processing capacity.

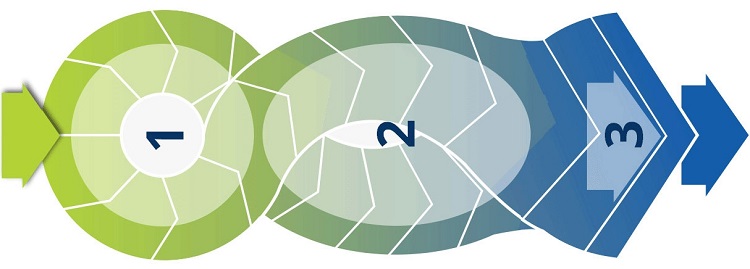

What is Three-step Sieving for Rotex Screener?

Three-step sieving process is composed of three different sieving motion, circular motion, elliptical motion and reciprocating motion.

The circular motion happens at the feeding port. Under this motion, the materials will rapidly spread across the full width of screen, so that the materials can get sufficient screening and move forward.

The second motion is elliptical motion. When the materials move to the center, they will have one long-stroke elliptical action, during this process, the materials will get sufficiently stratified at high speed.

At the final position, the materials will take one reciprocating motion to make sure the near-size particles will be separated. Also during the entire three-step sieving process, the materials will be always contacting with the screen surface. The screening efficiency and precision will be guaranteed.

Three-step Sieving Motion of Rotex Screener

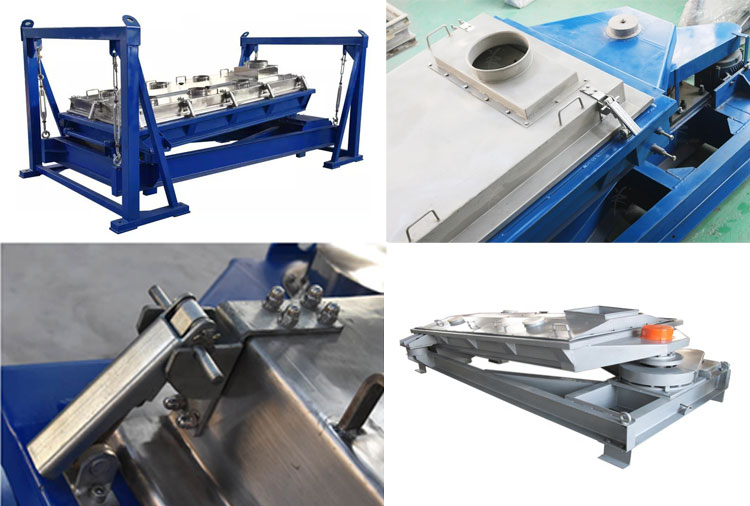

Характеристикыжы дӓ яжо:

- Extra large capacity from tens to hundreds of tons——Rotex screener is created to figure out the need of large capacity output.

- Professional Engineering Structure——The perfect machine structure guarantee one fully enclosed space for the sieving materials, then during the screening process, there will be no materials leaking or polluting the work area.

- The Protection of Materials——Without vertical force caused by vibration motor, the materials will not hit the screen surface and get damaged by the impact.

- Easy to Inspection—— The entire sieving process can be easily inspected and controlled by the workers.

How to Choose the Suitable Rotex Screener

Before you choose the rotex screener, your should let our engineers have the detailed information about your use condition, such as what materials you will handle, what sizes you want, what capacity you need and other necessary information you want us know. After that, our professional engineers will do the calculation and make design drawing for you reference. After your confirmation, the production process will begin. You will receive the inspection images and videos during our production, and once the production is finished and every detail is confrimed, the rotex screener will be shipped to your destination.